Particulate photocatalyst sheet efficiently driving the overall water splitting reaction

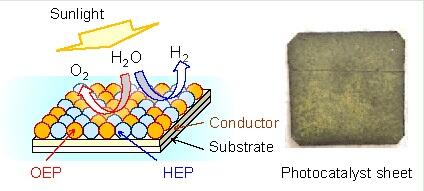

Sunlight-driven water splitting has been studied as a technology for producing renewable hydrogen on a large scale.1) The Z-scheme system that utilizes two-step excitation of a hydrogen evolution photocatalyst (HEP) and an oxygen evolution photocatalyst (OEP) is suitable for application of narrow bandgap photocatalysts, because photocatalysts can be applied to water splitting if they are active either in the hydrogen evolution reaction or the oxygen evolution reaction.

For the Z-scheme water splitting reaction to proceed, it is necessary to recombine photoexcited electrons and holes remaining in the OEP and the HEP, respectively. Conventionally, redox reactions of redox couples and physical contact of photocatalyst particles have been used for the electron transfer, but the water splitting activity tends to be low because of reverse reactions and contact resistance, respectively. To solve such problems, the author's group developed a particulate photocatalyst sheet in which HEP and OEP particles are mixed and fixed onto a conductive material by using the particle transfer method, which is a method for producing photoelectrodes of particulate semiconductors with low contact resistance.2)

The photocatalyst sheet has excellent electron transfer efficiency between HEP and OEP particles and is less susceptible to solution resistance and mass transfer resistance. Therefore, it shows high water splitting activity even in pure water, and the activity does not decrease even if the sheet size is increased. The photocatalyst sheet with optimized fabrication and reaction conditions has achieved a solar-to-hydrogen energy conversion efficiency of approximately 1% at atmospheric pressure, which is the highest level in the world, so that the generation of hydrogen and oxygen bubbles can be visually observed.3) In addition, large photocatalyst sheeta can be readily produced by utilizing coating processes. Recently, photocatalyst sheets made of non-oxide photocatalysts that respond to long-wavelength visible light have also been studied. These advances hold promise for further improvements in performance and large-area processing.

1) T. Hisatomi et al., Nat. Catal. 2019, 2, 387.

2) Q. Wang et al., Nat. Mater. 2016, 15, 611.

3) Q. Wang et al., J. Am. Chem. Soc. 2017, 139, 1675

HISATOMI Takashi, Research Initiative for Supra-Materials, Interdisciplinary Cluster for Cutting Edge Research, Shinshu University